Most people are familiar with 3 states of matter being solid, liquid, and gas but a lot of people are not familiar with the 4th. The fourth state of matter is plasma defined as an ionized gaseous mixture consisting of highly charged positive ions and free electrons (negative charge) that result in little or no electric charge. The amount of energy in each state of matter increases as you progress. Plasma is typically created at low pressures or at very high temperatures. Believe it or not plasma is the most common form of matter in the universe. [taken from definition, wiki, and general knowledge]

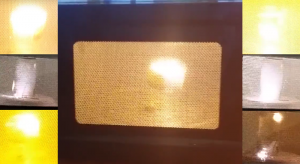

Examples of plasma are neon signs, CFL bulbs, lightning strikes and probably what I’m most interested in Fusion (the sun). Uses of plasma can be found in the manufacturing of electronic components such as semiconductors, metal plating of glass/silicon/etc, mineral extraction, ion propulsion and one day a very clean and efficient energy source.

Plasma conducts electricity and can be manipulated with a magnetic field. These properties are at the core of what I want to accomplish with the plasma chamber.

Experiments for the chamber

- Small scale plasma accelerator

- Plasma sputter plating of metals on to glass

- Ion drive simulation

- Magnetic containment fields

- Effect of plasma being pushed through a coil

- Plasma being formed with various gases and/or particle filled gases

- Custom waveguide antennas to concentrate energy for various applications

- Effect of electricity being applied across plasma

- Effect of shooting electrons through plasma

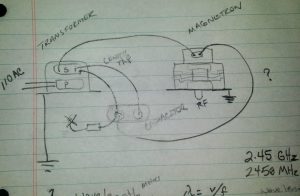

- Find a way to manipulate power and frequency of RF signal

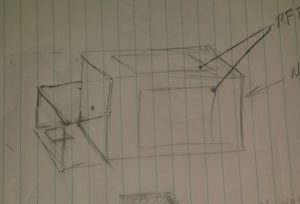

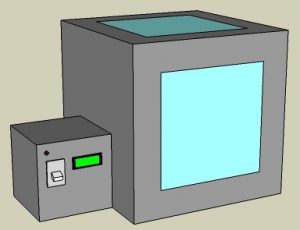

Microwave Plasma Chamber Part 1 & Part 2

Click here to browse through posts written about my interests in Microwave Projects

You must be logged in to post a comment.